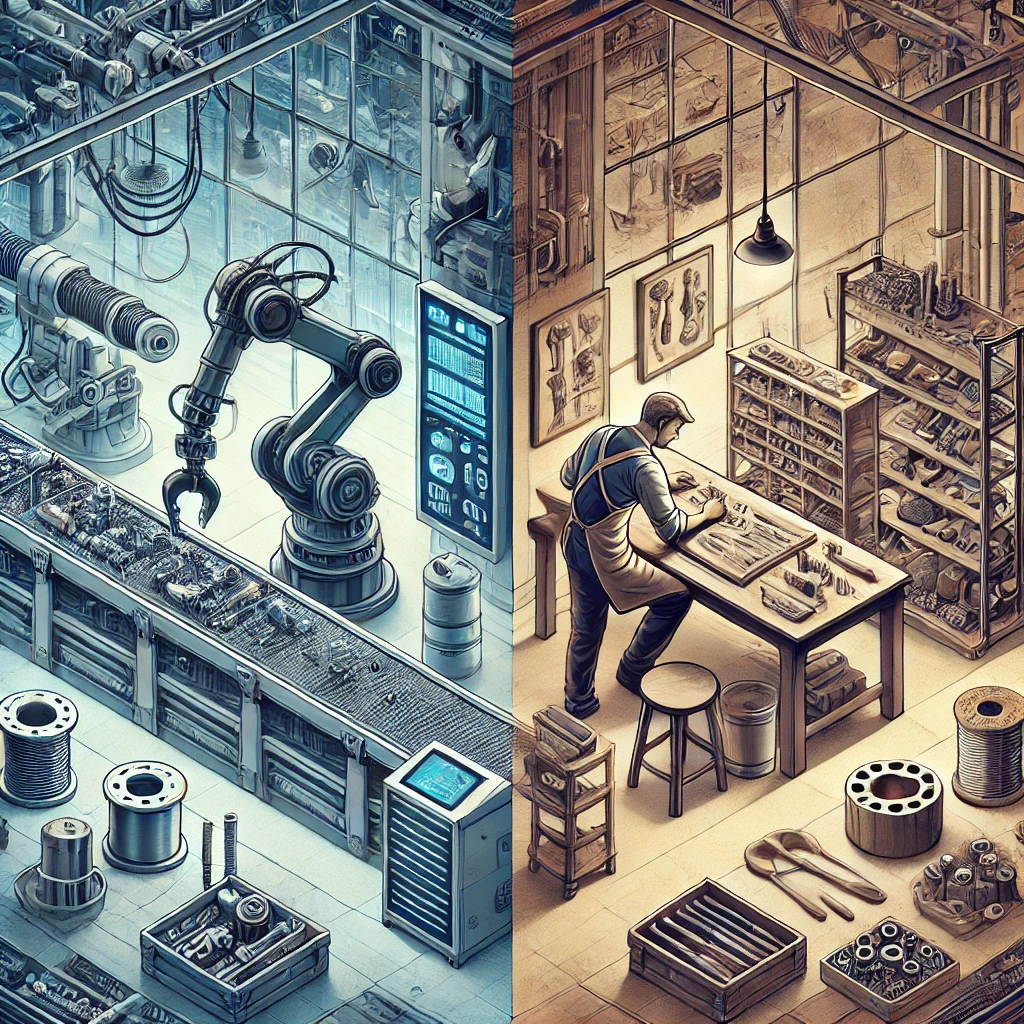

When it comes to finishing a project, be it a publication, handcrafted item, or a product for mass distribution, the decision-making process often hinges on a critical question: Should you rely on automation or opt for handwork? Both approaches have distinct merits and challenges, making the choice more nuanced than it appears at first glance.

Selecting the right finishing method requires careful consideration of your project’s specific needs. Are you producing a large volume of items where efficiency and speed are paramount? Or do you need a customized, artisanal touch to make your product stand out in a competitive market? These are just a few factors to weigh before deciding between automation and handwork.

It’s important to recognize that there’s no “one size fits all” solution. Each project has unique requirements based on factors like scale, budget, desired quality, and the timeline for completion. While automation might be ideal for high-volume tasks requiring precision, handwork brings a personal touch and craftsmanship that no machine can replicate.

Understanding Automation

Automation refers to the use of machines and technology to perform tasks that would otherwise require manual effort. In the context of finishing services, automation has transformed industries by streamlining processes, improving efficiency, and enabling large-scale production. By employing specialized machinery such as die cutters, laminators, binders, or paper folding machines, automation simplifies complex tasks and delivers consistent results.

One of the key applications of automation is die cutting, which is used to shape materials into precise, uniform designs. Another popular process is laminating, where layers of protective film are applied to materials, enhancing durability and appearance. Binding is yet another common automated task, particularly useful for assembling books or publications quickly and with professional quality.

Automation is characterized by its ability to handle repetitive tasks with speed and precision. For instance, binding machines can assemble hundreds of pages in a single step, saving hours of manual effort. Many machines in this category heat up and become operational within minutes, ensuring minimal downtime and high productivity.

The core capabilities of automation include:

- Efficiency: Automation significantly reduces the time needed for tasks that would take hours or days by hand.

- Scalability: Machines are ideal for high-volume projects, making them an excellent choice for businesses that need to meet large-scale demands.

- Consistency: Unlike manual work, automated processes produce uniform results with minimal risk of human error.

- Cost-Effectiveness: While the initial investment in machinery can be high, automation lowers long-term production costs by reducing labor hours and increasing output.

Automation is particularly advantageous for businesses that prioritize speed, accuracy, and cost efficiency over customization. It allows companies to meet tight deadlines and produce large quantities of finished products without compromising on quality. However, while automation is highly effective for mass production, it may lack the flexibility and personal touch that certain projects demand an aspect where handwork shines.

Understanding Handwork

Handwork refers to the use of manual labor to complete tasks that machines often handle in automated processes. In a world increasingly dominated by automation, handwork has found a unique and growing appeal. It represents craftsmanship, attention to detail, and a sense of authenticity that machines simply cannot replicate. For projects that require personalization, high-quality finishes, or a touch of artistry, handwork often stands out as the preferred choice.

Unlike automation, which focuses on efficiency and large-scale production, handwork emphasizes individuality and customization. This approach is particularly valued in industries like boutique publishing, luxury packaging, and artisan goods, where the final product reflects a commitment to quality and uniqueness.

There are numerous handwork finishing techniques, each adding its own charm to the final product. Some common examples include:

- Hand Gluing: This technique is often used for assembling intricate parts, applying embellishments, or securing delicate materials. The precision of hand gluing ensures that each piece is treated with care.

- Hand Folding: Ideal for projects like brochures, invitations, or custom packaging, hand folding allows for creative folds and designs that machines might struggle to execute perfectly.

- Packaging: Whether it’s wrapping a luxury product in tissue paper or assembling gift boxes, manual packaging creates a tactile and memorable experience for the end user.

The appeal of handwork lies in its ability to deliver finishes that are not only high-quality but also inherently unique. Each piece carries the subtle imperfections and craftsmanship that tell a story—a feature many customers value in an era of mass production.

As automation takes over repetitive and large-scale tasks, handwork is increasingly sought after for its ability to provide a human touch. It is particularly well-suited for small-scale projects, limited-edition runs, and items where aesthetics and individuality are paramount. By leveraging handwork, businesses and individuals can create products that resonate with a discerning audience seeking something special and personal.

Benefits and Drawbacks of Automation

Automation offers a wide array of benefits, particularly for industries and projects where speed, efficiency, and scalability are key priorities. However, it also comes with certain limitations and challenges that need to be carefully considered. Below is a balanced look at the advantages and drawbacks of relying on automation.

Benefits of Automation

- Increased Production Speed and Efficiency

Automation drastically reduces the time required to complete tasks. Machines can perform repetitive actions at speeds that far surpass human capabilities, enabling businesses to meet tight deadlines and handle large orders with ease. - Cost-Effectiveness for Large-Scale Projects

While the upfront cost of automation equipment can be significant, it pays off in the long run, especially for high-volume production. Automated systems reduce labor costs, minimize waste, and optimize resource utilization, making them a cost-effective choice for large-scale operations. - Consistent Product Quality

Automated machines excel in delivering uniform results with minimal errors. Whether it’s die-cutting, binding, or laminating, automation ensures every product meets the same high-quality standards, a crucial factor for industries that value precision and consistency. - Improved Working Conditions in Industrial Settings

By taking over repetitive or labor-intensive tasks, automation reduces the physical strain on workers. This leads to a safer and more comfortable working environment, as employees can focus on supervisory roles or tasks requiring creativity and problem-solving.

Drawbacks of Automation

- High Initial Investment

The cost of purchasing and installing automated machinery can be a significant barrier, particularly for small businesses or startups. Additionally, ongoing expenses such as training, maintenance, and energy consumption add to the total cost of ownership. - Limited Flexibility for Customization

Automation is designed for efficiency and uniformity, which can make it less adaptable for projects that require personalization or intricate details. This rigidity can be a disadvantage in industries where uniqueness is a selling point. - Potential Ethical Concerns Regarding Workforce Reduction

As automation replaces manual labor, it raises ethical and societal concerns about job displacement. This is particularly challenging in industries where employment opportunities rely heavily on manual tasks. - Hidden Maintenance or Operational Costs

Beyond the initial purchase, automation involves ongoing expenses such as repairs, software updates, and machine downtime. These costs can add up unexpectedly, affecting the overall budget and profitability.

Striking a Balance

Automation is a powerful tool for businesses that need to scale up production, maintain quality, and optimize efficiency. However, it’s essential to weigh its drawbacks, particularly when considering smaller, specialized projects or businesses with limited budgets. By understanding both sides of automation, you can determine whether its benefits align with your specific needs and goals.

Benefits and Drawbacks of Handwork

Handwork remains a popular choice for projects that prioritize uniqueness, craftsmanship, and a personal touch. It offers advantages that automation cannot replicate, but it also comes with certain limitations, particularly when scaling for larger operations. Here’s a closer look at the benefits and drawbacks of handwork.

Benefits of Handwork

- Unique and Customizable Finishes That Stand Out

Handwork allows for a level of customization and individuality that automated systems cannot achieve. Whether it’s a handcrafted binding or intricate folds, the result is a distinctive product that conveys care and attention to detail. This uniqueness is especially appealing in niche markets, luxury goods, and artisan industries. - Cost-Effective for Smaller Projects

For small-scale productions, handwork can be more economical than investing in automation. Without the need for expensive machinery or setup costs, it becomes a practical choice for limited-edition runs, prototypes, or personalized projects. - Ability to Print on Demand Without Minimum Orders

Unlike automated processes that may require minimum order quantities to justify costs, handwork allows for on-demand production. This flexibility is ideal for independent creators, small businesses, or projects where only a few units are needed. - High-Quality, Artisanal Touch

Hand-finished items often exude a level of quality and craftsmanship that resonates with customers. The artisanal appeal adds value to the product, making it particularly attractive in markets where authenticity and craftsmanship are highly prized.

Drawbacks of Handwork

- Slower Production Times

Manual processes naturally take longer than automated ones, making handwork less suitable for projects with tight deadlines or high-volume requirements. Each piece requires individual attention, which can significantly extend production timelines. - Higher Labor Costs

The reliance on skilled workers increases the cost of handwork. Labor-intensive tasks, especially those requiring a high degree of precision or creativity, can quickly add up, making this option less cost-effective for larger-scale projects. - Increased Shipping Weight for Certain Finishes

Some hand-finishing techniques, such as case binding or adding embellishments, can increase the weight of the final product. This not only raises shipping costs but may also complicate logistics for large orders. - Limited Scalability for Larger Orders

While handwork excels at small, detailed projects, it struggles to meet the demands of large-scale production. Scaling up requires a significant increase in labor and time, making it impractical for high-volume needs.

Finding the Right Fit

Handwork is ideal for projects where quality, uniqueness, and customization take precedence over speed and cost. It shines in smaller, specialized projects or for businesses seeking to create a lasting impression with high-quality finishes. However, its limitations in scalability and efficiency mean it’s not always the best choice for every situation. Understanding these pros and cons can help you decide whether handwork aligns with your project’s goals and requirements.

Factors to Consider When Choosing

Deciding between automation and handwork for finishing services requires careful evaluation of your project’s specific needs and priorities. Both methods have unique advantages and drawbacks, so it’s important to weigh the following factors before making your choice:

1. Type and Purpose of the Publication or Project

The nature of your project plays a significant role in determining the appropriate finishing method. For example:

- Marketing Materials: Large-scale brochures or flyers often benefit from automation due to the need for quick and consistent production.

- Artisan or Luxury Products: Projects like handcrafted books, wedding invitations, or bespoke packaging are better suited for handwork to achieve a personalized and high-quality finish.

Consider whether the end product needs to convey uniqueness or if efficiency and consistency are the main priorities.

2. Number of Copies Needed

The size of your production run is another critical factor.

- Large Quantities: Automation is ideal for bulk orders as it reduces time and cost per unit while maintaining uniformity.

- Small Quantities: Handwork is more practical for limited editions or one-off pieces, as it avoids the high setup costs associated with automation.

3. Budget Constraints

Your financial resources can heavily influence your choice.

- Automation: While the initial investment in machinery or outsourcing automated services may be high, it becomes cost-effective for large-scale projects due to reduced labor costs and faster production.

- Handwork: Although handwork may appear less expensive upfront for small projects, the labor-intensive process can become costly for larger orders or intricate designs.

Balancing your budget with the project’s requirements will help guide your decision.

4. Importance of Quality and Uniqueness in the Final Product

The level of detail and personalization needed in the finished product is a key consideration.

- Automation: Best for achieving consistent, professional results, particularly when high precision and repeatability are necessary.

- Handwork: Ideal for creating a one-of-a-kind, artisanal touch that stands out in a market saturated with mass-produced goods.

5. Timeline for Project Completion

Deadlines often dictate the feasibility of choosing one method over the other.

- Automation: Perfect for tight schedules as it significantly reduces production time, making it suitable for high-volume orders with urgent deadlines.

- Handwork: Requires more time due to its manual nature, making it better suited for projects where quality and customization outweigh the need for speed.

Balancing the Factors

No single method fits all projects, so it’s essential to evaluate these factors holistically. If you’re producing high-volume, time-sensitive materials, automation may be the best choice. On the other hand, if your project demands a personal, unique touch or involves a smaller run, handwork might better align with your goals. Ultimately, understanding your project’s type, scope, and constraints will help you make an informed decision tailored to your needs.

Comparison Chart: Automation vs. Handwork

Below is a clear and concise summary of the key differences between automation and handwork, helping you compare the two methods based on crucial criteria.

| Criteria | Automation | Handwork |

| Cost | High initial investment, cost-effective for large-scale production. | Lower setup costs but higher labor costs, especially for larger projects. |

| Time | Fast production, ideal for tight deadlines and bulk orders. | Slower production, requiring more time for intricate or manual finishes. |

| Scalability | Excellent for high-volume orders with consistent quality. | Limited scalability; better for small-scale or personalized projects. |

| Quality | Consistent and precise, ideal for standard finishes. | High-quality, artisanal touch that conveys craftsmanship. |

| Customization | Limited flexibility; works best for uniform, repetitive designs. | Highly customizable, offering unique and tailored finishes. |

Key Takeaways

- Choose Automation for efficiency, speed, and cost-effectiveness in large-scale or repetitive projects.

- Opt for Handwork when customization, quality, and a unique finish are priorities, especially for small-scale productions or niche markets.

Read more: HAT’s the way to do it: what are Raspberry Pi HATs, and how could you use them?

Final Thoughts

When deciding between automation and handwork for your finishing services, there’s no universal answer it all depends on your project’s unique requirements. Automation shines in efficiency, scalability, and cost-effectiveness for high-volume projects, while handwork offers unmatched customization and a personal touch that can make your product stand out in a competitive market.

Key considerations like the type of project, quantity needed, budget, and desired quality should guide your decision. Automation is the go-to choice for quick turnarounds and uniform production, making it ideal for mass-produced materials. On the other hand, handwork is perfect for creating bespoke, high-quality items where detail and individuality are paramount.

Ultimately, the best choice is one that aligns with your goals, timeline, and audience expectations. Whether you opt for automation, handwork, or even a combination of both, understanding their strengths and limitations will empower you to make an informed decision that enhances your project’s success.